Workshop

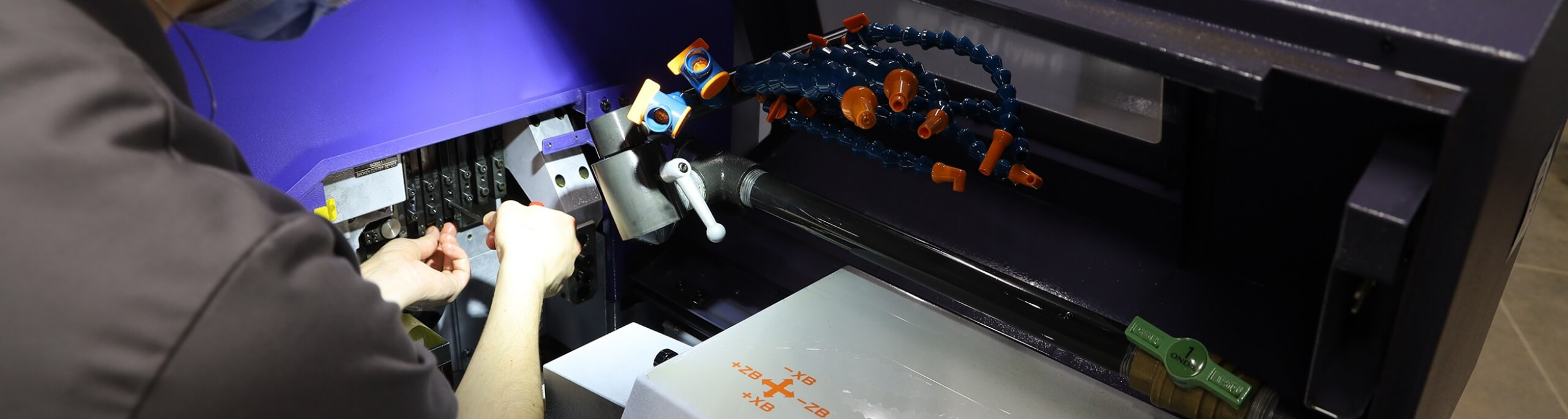

The performance of our machine park

PERRENOUD's production facilities cover more than 1,300 square metres where numerically controlled machines are installed. This equipment is recent, which guarantees our customers precision in the turning of parts and performance in the execution of work.

These numerical control machines are of the STAR and MANURHIN KMX brands. This production tool is adapted to allow us to be reactive to customer demand.

The performance of this machine park also depends on the technical skills of PERRENOUD's employees.

Systematic

quality control

In addition to this machine park, we also have high-performance inspection equipment such as profile projectors and measuring microscopes. Metrology is essential to our inspection operations, as is the aesthetics of the parts.

The rework workshop

PERRENOUD also has a rework workshop where all types of parts are processed, including parts directly supplied by our customers. In this workshop, the parts can be diamond-coated, an operation that gives them a very good surface finish.

Our production methods

-

14 numerically controlled lathes with 6 axes -

capacity diameter 1 to 10 mm -

3 numerically controlled lathes with 3 axes -

capacity diameter 6 to 20 mm -

2 CNC lathes with 8 axes -

capacity diameter 6 to 20 mm -

3 CNC lathes with 10 axes -

capacity diameter 6 to 20 mm -

1 CNC lathe with 8 axes -

capacity diameter 15 to 42 mm

VARIOUS REWORKING MACHINES

- 4 3-axis CNC lathes for diamond reshaping

- 2 posalux

Our measurement

methods

- 3 profile projectors

- 3 measuring microscopes

- Micrometer, gauges, calipers, roughness tester, etc.

3 profile projectors

3 measuring microscopes

Micrometer, gauges, calipers, roughness tester, etc.